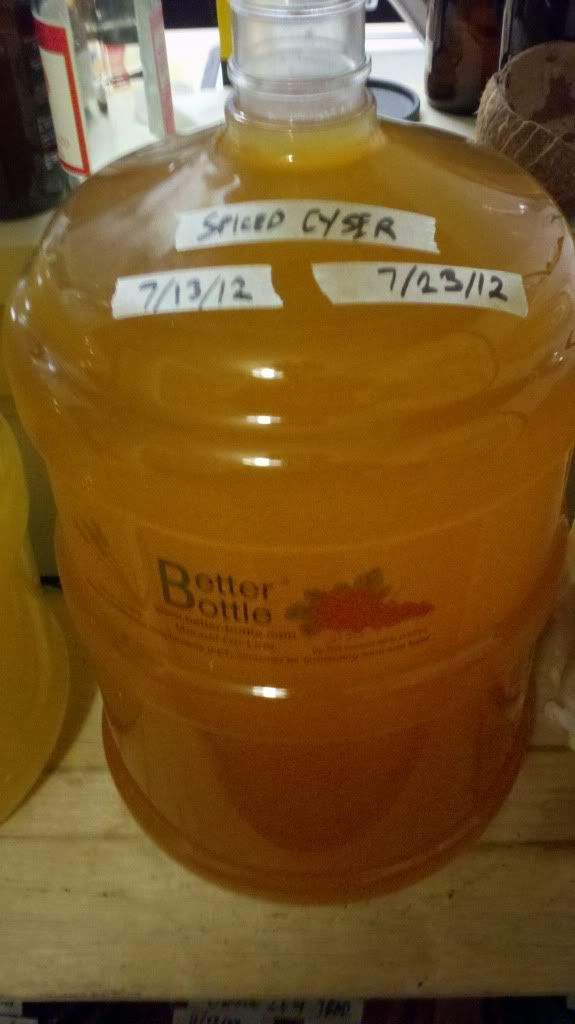

Spiced Cyser

-----------------------------------------

Initial SG: 1.106

Initial Volume: 5.33 Gallons

Yeast: K1v-1116 (10g)

Fermaid-O: 82.4g (160ppm YAN)

Go-Ferm: 13g (19ppm YAN)

H2O: 250ml Bottled Drinking Water

Ferm-Cap: 1 Dropper plus 2 drops in Yeast Starter

Honey: ~9 lbs Winco Clover

Juice: 4.5 Gallons of Kroger Brand Apple Juice (SG = 1.050)

Procedure:

--------------------------------------------------------

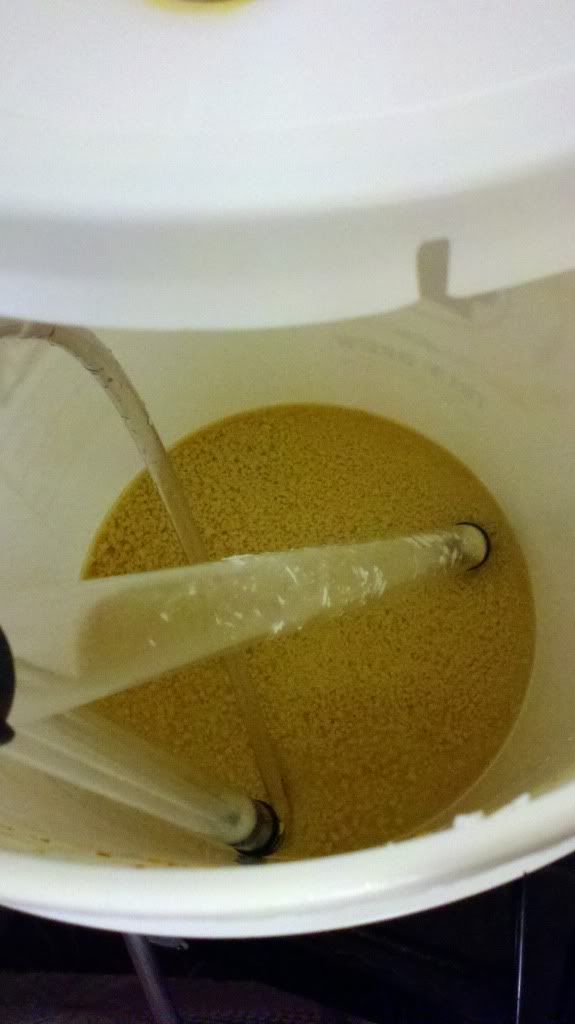

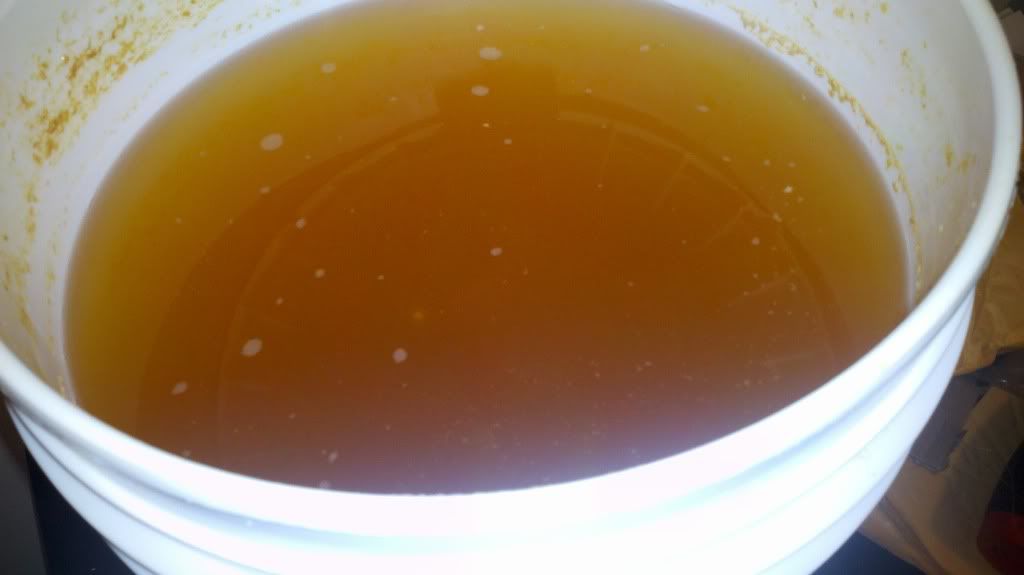

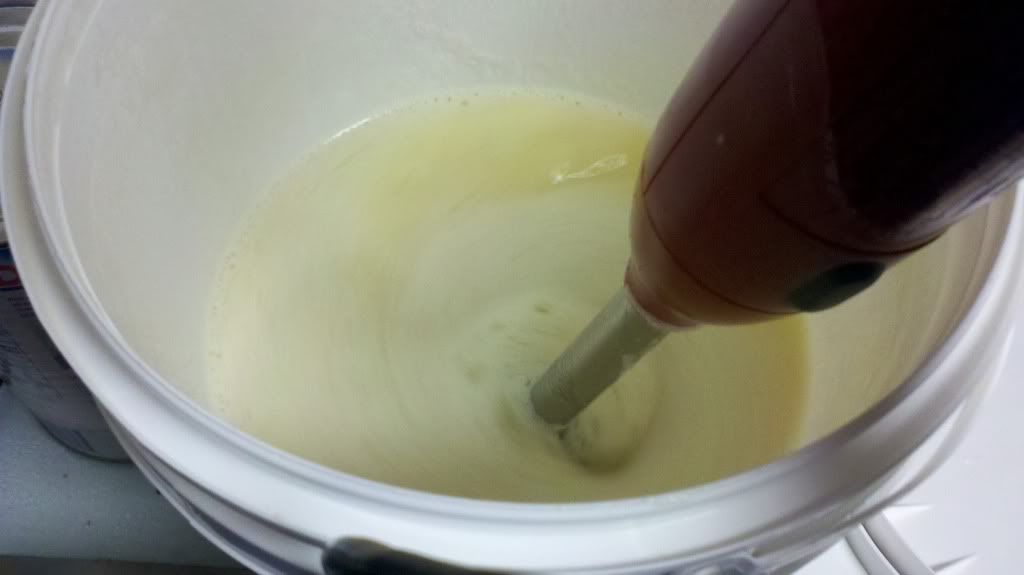

Heat honey to warm and whip it into the apple juice in a plastic bucket fermenter.

Aerate for 15 minutes using an air stone.

Rehydrate yeast in Go-Ferm per directions.

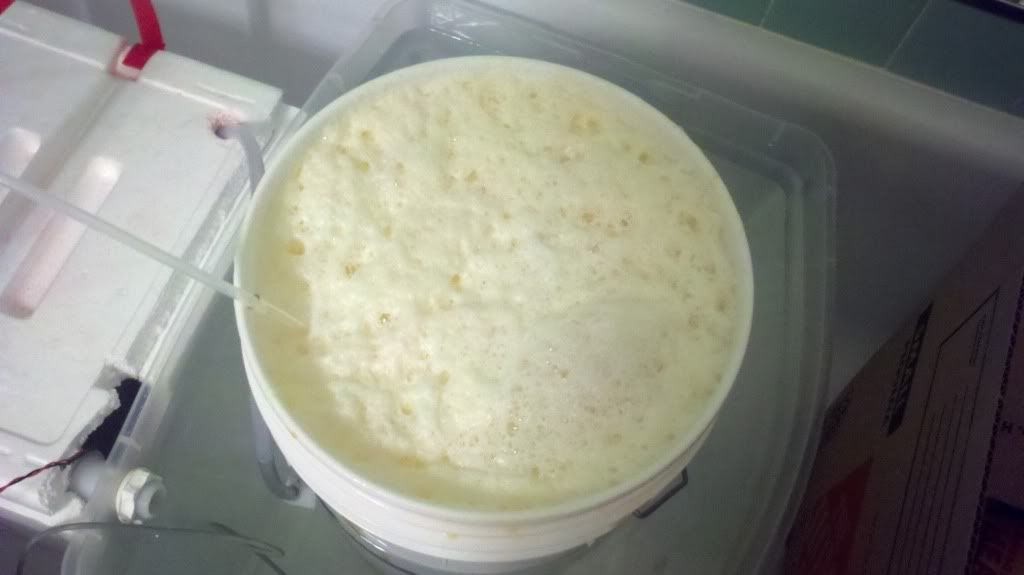

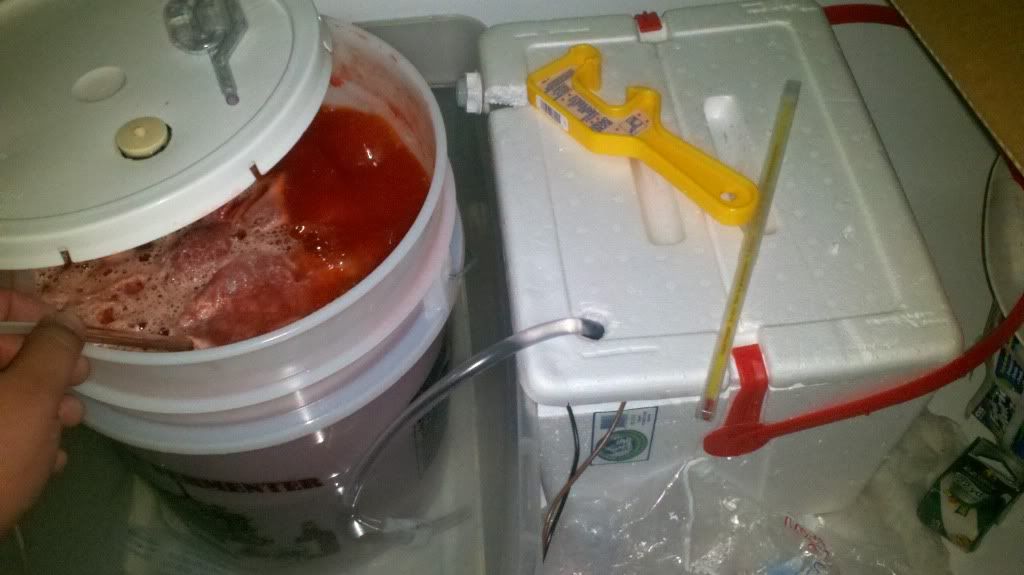

Pitch yeast and place into a temperature controlled water batch set for 15C.

Day 0 - 9:20PM

------------------------------------

------------------------------------

pH: 4.0

Temperature: 78F

Initial SG: 1.106

Initial Volume: 5.33 Gallons

Yeast: K1v-1116 (10g)

Fermaid-O: 82.4g (160ppm YAN)

Go-Ferm: 13g (19ppm YAN)

H2O: 250ml Bottled Drinking Water

Ferm-Cap: 1 Dropper plus 2 drops in Yeast Starter

Honey: ~9 lbs Winco Clover

Juice: 4.5 Gallons of Kroger Brand Apple Juice (SG = 1.050)

Must Temperature @ Pitch: 76F

Yeast Temperature @ Pitch: 80F

Pitched: 7/7/12 9:20PM

Corrected SG @ 60F = 1.108

Day 0 - 11:20 AM (14 Hours)

------------------------------------

------------------------------------

Calibrated pH meter - It was off by -0.1 point

Sanitary Aeration for 5 minutes through air stone

SG = 1.104

Temperature = 60F

pH = 4.0

Day 2 - 12:00 AM (27 Hours)

------------------------------------

------------------------------------

Sanitary Aeration for 5 minutes through air stone

SG = 1.098

Temperature = 60F

pH = 4.0

Added 3.25g Fermaid-K - (16ppm YAN) Total YAN = 195ppm

Day 2 - 12:20PM (39 Hours)

------------------------------------

------------------------------------

Sanitary Aeration for 5 minutes through air stone

SG = 1.083

Temperature = 62F

pH = 4.0

Added 4g DAP - (42ppm YAN) Total YAN = 236ppm

Day 3 - 9:20 AM (48 Hours)

------------------------------------

------------------------------------

H2S Detected - Very Slight

Sanitary Aeration for 5 minutes through air stone

SG = 1.060

Temperature = 64F (Coolant off for last 6 hours. It is back online now)

pH = 3.9

Added 6.5g Fermaid-K - (42ppm YAN) Total YAN = 278ppm

Added 9g Fermaid-O - (18ppm) Total YAN = 296 ppm

Added 1 more dropper of Ferm-Cap to knock down foam...

Day 3 - 10:20 PM (48 Hours)

------------------------------------

------------------------------------

H2S Detected - Stronger

SG = 1.042

Temperature = 62F

pH = 3.9

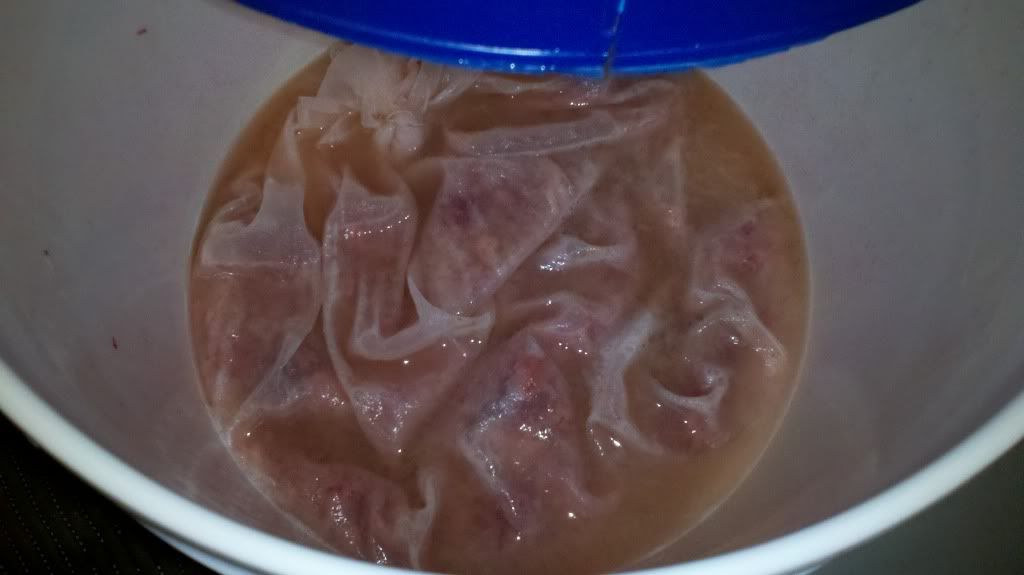

Added 15g Boiled Baker's Yeast - (30ppm YAN) Total YAN = 327ppm

Slight Stir

7/11/12 8:20AM

------------------------------------

------------------------------------

H2S Detected - Very very slight

SG = 1.032

Temperature = 62F

pH = 3.9

Slight Stir

7/11/12 8:00PM

------------------------------------

------------------------------------

SG 1.023

pH 4.1

62F

Slight Stir

7/12/12 9:30AM

------------------------------------

------------------------------------

SG 1.016

pH 4.0

62F

Slight Stir

7/12/12 10:30PM

------------------------------------

------------------------------------

SG 1.011

pH 4.0

64F

Slight Stir

Turned Off Cooling

7/13/12 10:20PM

------------------------------------

------------------------------------

SG 1.008

pH 4.1

66F

Swirled

Moved to Shelf

7/14/12 11:59PM

------------------------------------

------------------------------------

SG 1.008

pH 4.1

74F

Swirled

7/23/12 9:18PM

------------------------------------

------------------------------------

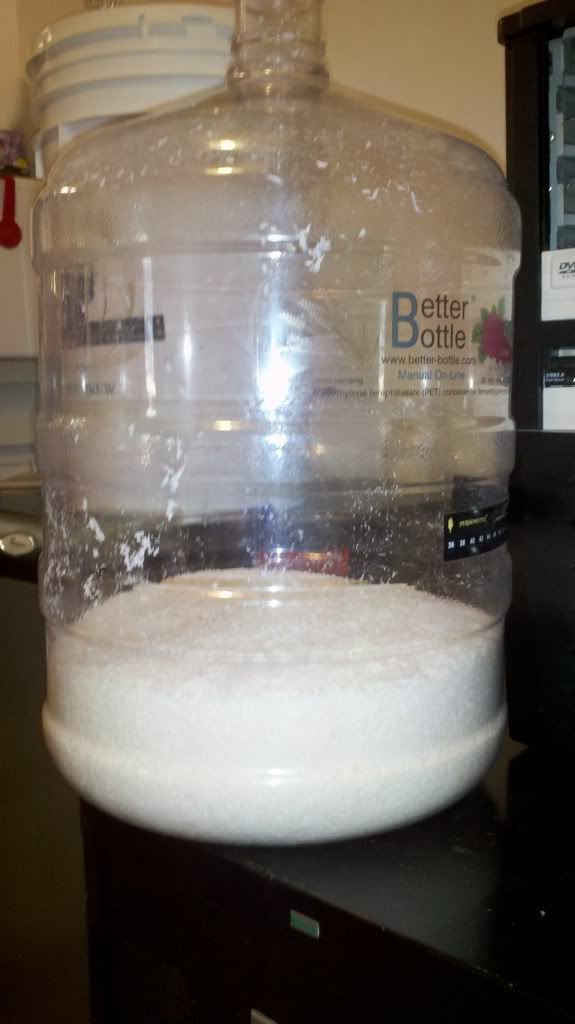

Racked into 5 gallon BB

pH = 4.1

SG = 1.005

Appearance - Cloudy

Smell - Very much like wine. Clean. No SO2 odours. Promising

Taste -

Added 5.3g of K-Meta. The targets are (160ppm Free) (0.80 Molecular)

I am going to wait 3-4 days then check free SO2 using a titret. Based on the ratio that was bound I will calculate the addition to bring the Free SO2 to the target range...